HAPPC

What is it?

HACCP means Hazard Analysis and Critical Control Points. The purpose of this system is to adopt preventive methods to guarantee safety. Food regulations make it compulsory for all food businesses to have a preventive system in place based on HACCP principles. This system can be more or less complex depending on the characteristics of the establishment, which is why APTHISA can advise you on the most appropriate plan : HACCP, good manufacturing practices or traceability requirements.

At APTHISA we are experts in designing, implementing and validating any type food safety plan.

Which one to implement?

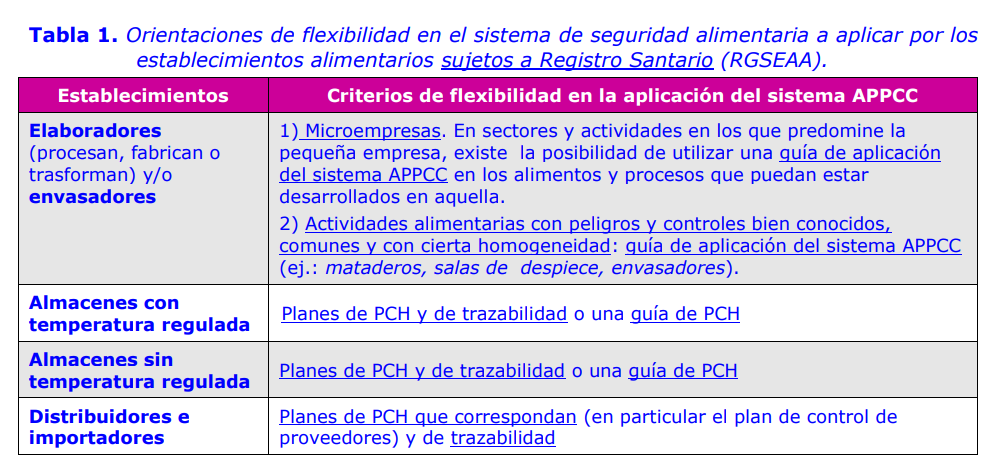

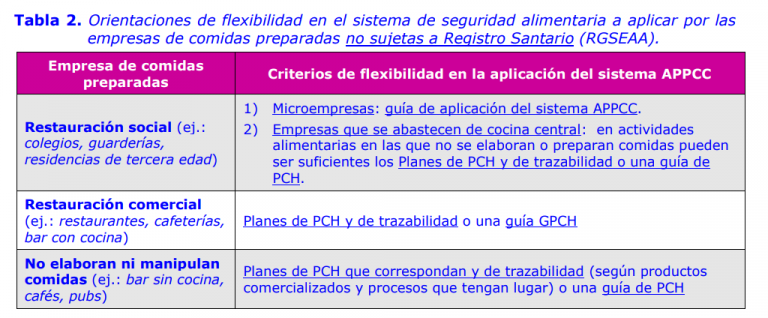

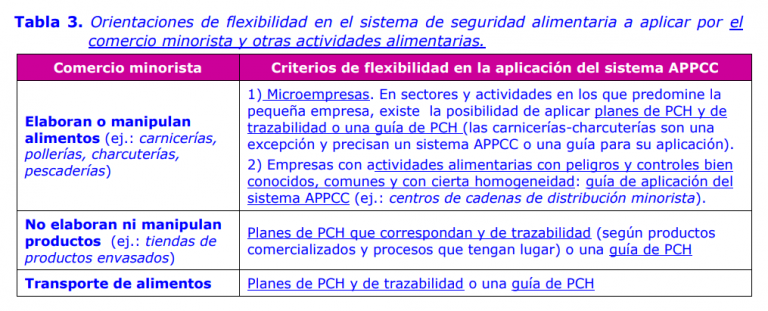

Food regulations establish flexibility criteria for the implementation of the HACCP plan depending on the type of food establishment. Thus, although hazards affecting the food production process must always be identified in certain establishments good hygiene practices and good manufacturing practices (prerequisites) can be considered enough to control hazards and guarantee the safety of food.

Here can be found more information on this subject, applicable to all EU countries.

In addition, guides have been published in each community to clarify the flexibility criteria. In the case of Madrid they would be as follows:

Source: Guidelines for flexibility in the application of Food Safety Systems based on HACCP principles in the Community of Madrid (Dirección General de Salud Pública, Consejería de Sanidad) edition 03.

What are the steps to be followed for its elaboration?

- Diagnostic audit: The first step is a visit to the establishment to collect documentation, facility plans, work procedures and methodologies as well as other relevant data to be applied in the design of the food safety plan based on HACCP.

- Design by APTHISA: a multidisciplinary team designs the plan, considering all the possible dangers that may be detected depending on the process carried out by the establishment. Depending on the complexity of each case, the design time may vary. However, on average it is usually between 3 and 8 weeks.

- Delivery of the plan in the establishment: the structure and work methodology derived from its implementation will be explained to the establishment's personnel (documentation to be attached, registers to be filled in and tasks to be carried out).

- Implementation of plan: for a correct implementation, APTHISA recommends some complementary activities, with varying frequency depending on the characteristics of the establishment: training, food safety audits, food sampling, equipment checks…

Once it is designed, what needs to be done?

The food safety plan is not a static element. It must grow and change as the establishment does, so that it is always in line with the establishment.

For this reason, we recommend having a follow-up of it. At APTHISA we achieve this doing food safety audits, these help both to detect opportunities for improvement and to evaluate the implementation of thefoos safety plan in place.

In addition, to reinforce the implementation, the following can be carried out: laboratory samples, equipment checks or training al personal.